Have you ever wondered how advanced manufacturing processes are able to achieve such precision and efficiency? The answer lies in the incredible technology of picosecond pulsed lasers. These cutting-edge lasers have revolutionized the manufacturing industry, allowing for unprecedented levels of accuracy and speed.

The Power of Picosecond Pulsed Laser

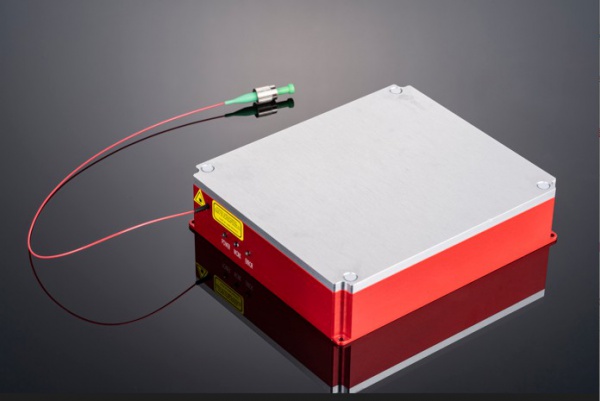

Picosecond pulsed lasers emit ultra-short pulses of light that last only picoseconds (trillionths of a second). This rapid pulse duration enables them to deliver an immense amount of energy in an incredibly short period. By harnessing this power, manufacturers can perform intricate tasks with unparalleled precision.

These lasers find applications in various industries, including electronics, aerospace, medical devices, and more. They are used for micro-machining delicate materials like semiconductors or ceramics, creating high-resolution 3D structures on surfaces, and even performing eye surgeries with minimal tissue damage.

The Role of WDM System and Fiber Optics

In addition to their remarkable capabilities, picosecond pulsed lasers also benefit from advancements in wavelength division multiplexing (WDM) systems. WDM allows multiple wavelengths to be transmitted simultaneously through a single optical fiber by using different colors or frequencies.

Dense Wavelength Division Multiplexing (DWDM) is a specific type of WDM system that enables the transmission of numerous wavelengths over long distances without interference. This technology has greatly enhanced data communication networks by increasing bandwidth capacity while reducing costs.

Find more about wdm system. dwdm wavelengths. wdm fiber. fiber optic wdm.

Fiber optic cables play a crucial role in supporting these advanced laser systems. With their ability to transmit light signals over long distances without significant loss or degradation, fiber optics ensure efficient delivery of laser energy precisely where it’s needed during manufacturing processes.

The Advancement of Optizone Technology

One notable development in the field of picosecond pulsed lasers is the introduction of Optizone Technology. This innovative approach optimizes laser beam quality and stability, resulting in even higher precision and reliability.

Optizone Technology utilizes advanced optics and control systems to shape the laser beam into a highly focused, uniform spot size. This ensures consistent energy delivery across the entire work surface, eliminating any potential irregularities or defects that could compromise manufacturing quality.

Furthermore, this technology allows for real-time monitoring and adjustment of laser parameters during operation. Manufacturers can now achieve optimal performance without interruptions or manual adjustments, leading to increased productivity and reduced downtime.

In Conclusion

Picosecond pulsed lasers have transformed the manufacturing industry by providing unprecedented levels of accuracy and speed. With their ultra-short pulse duration, these lasers enable intricate tasks with minimal damage to materials or tissues. The integration of WDM systems and fiber optic cables further enhances their capabilities by enabling efficient transmission over long distances. Additionally, advancements like Optizone Technology optimize laser performance for maximum precision and reliability. As we continue to push boundaries in manufacturing technology, picosecond pulsed lasers will undoubtedly play a vital role in shaping our future.